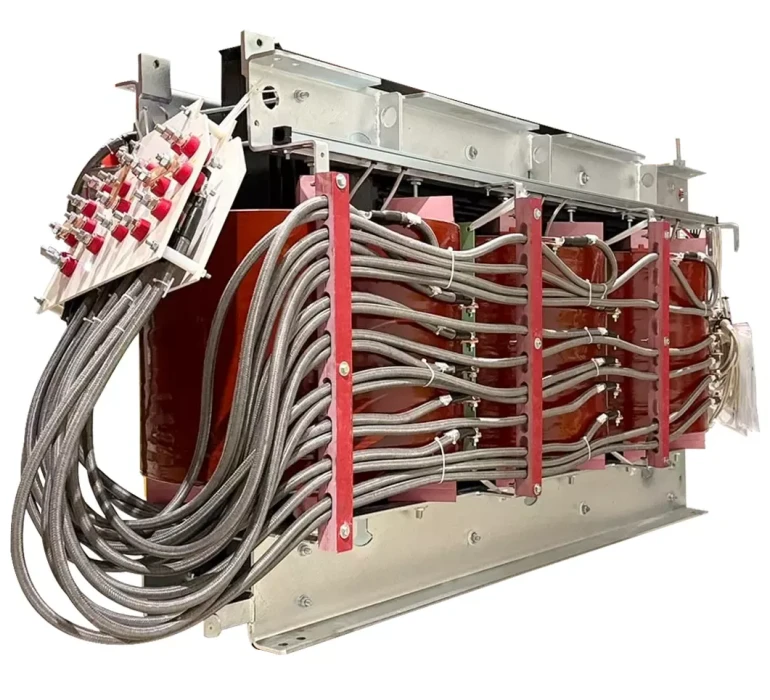

Resin Transformers for Rectifier Systems

These are two-winding or three-winding transformers designed to power 6-pulse or 12-pulse rectifiers. Each transformer design takes into account the magnitude of current harmonics flowing through the windings and the resulting increased heat dissipation in the windings.

These transformers are most commonly manufactured using the non-vacuum RESIGLAS technology.

Resin Transformers for Mining Stations

These are transformers designed for installation in flameproof enclosures and intended for operation in underground mines. They are characterized by very low height and low winding temperature rises—so that the allowable operating temperatures of the windings are not exceeded once enclosed. These transformers are designed to temperature class H – maximum winding temperature up to 180°C.

Basic Electrical Parameters:

- Rated power in kVA: from 400 to 1600

- Rated primary voltage in kV: 6.3

- Rated secondary voltage in V: 525, 1050, 1200, 3300

- No-load tap changer voltage regulation: ± 2 x 2.5%

- Connection group: Dy5, Yy0

- Short-circuit voltage: 4.5% or 6%

- Temperature class H

RESIGLAS Resin Transformers

The high-voltage windings of these transformers are manufactured as layer-type coils using the wet roving method. They consist of alternating layers of copper or aluminum conductors with Class H varnish insulation and layers of roving (glass fibers) impregnated with epoxy resin. The roving makes up 60% to 70% of the total composite mass. The roving bands are applied alternately longitudinally and diagonally. This structure forms a reinforcing mesh and provides exceptionally high mechanical strength to the entire composite. Therefore, the coils are resistant to cracking caused by temperature changes in the coils resulting from varying transformer loads. For this reason, transformers of this type are particularly suitable for applications with large load fluctuations and heavy overloads, such as rectifier systems or power supply for tram and metro traction.