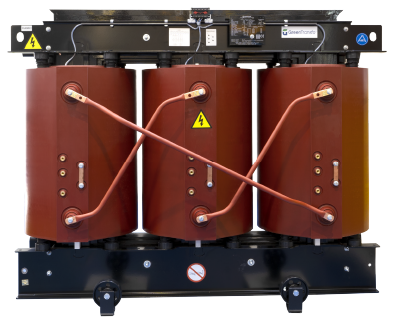

Dry Resin Distribution Transformers with vacuum technology

These are dry-type distribution transformers used for converting medium voltage electrical energy (6 kV to 35 kV) to low voltage (400 V to 420 V). The main insulation in these transformers is air.

The absence of oil or other insulating liquids makes them practically non-flammable, allowing installation close to energy consumers. They are especially well suited for supplying industrial plants, large stores, and high-rise buildings. They are primarily intended for indoor installations.